Dual Plate Flange Type Check Valve with Full Rubber

TC5

Flange type with fully lined dual check valve

Full rubber body dual plate flange check valves design with no external body penetrations eliminating the possibility of outside leakage. Because the body design with full rubber lined

The elevated costs and continuous variation in the prices of prime materials used for castings of alloyed materials for corrosion resistance is motivation to look for alternatives more economical or other type of constructions. Dual plate flange type check valve with full rubber is good choose. By this application costs can be reduced between 15% and 35% of the total valve cost compared with the body completely in alloy.

Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

Flange type valves are provided with thru-hole bolting in accordance with API 594,ASTM,JIS,ISO.

Wafer check valves look a lot like butterfly valves at first glance. They are narrow, which makes them great when there isn’t enough room for a bulky valve.

Rubber seat usually use in sea water. The inner body is full covered by rubber. Compared to other check valves, this design owns the better watertight effect.

Features

- Flange type check valve's bolt hole no tapping, it decrease cost on machining.

- Disassemble easily.

- Full rubber type 0 leakage.

- Body with full rubber lined can effectively reduce disc's leakage probability for the corrosion of sea water.

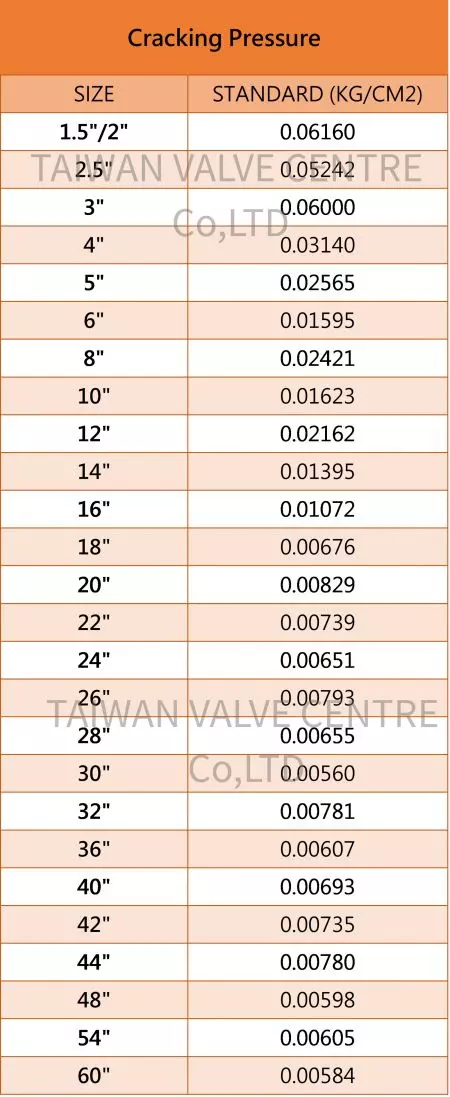

Specification

- Size: 8" ~ 60" (DN200 - DN1500)

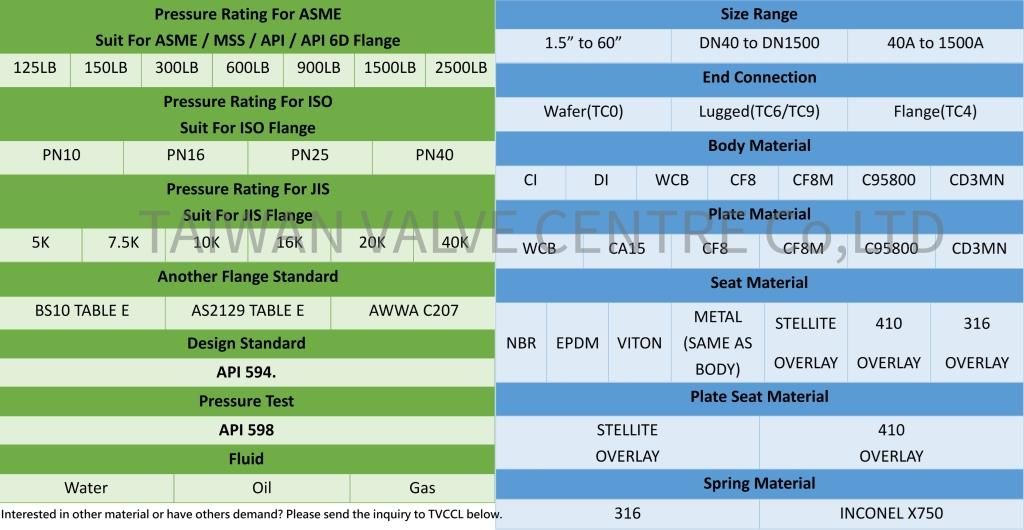

- Pressure Rating For ASME: 125# ~ 2500# Suit For ASME / MSS / API Flange

- Pressure Rating For ISO: PN10 ~ PN40 Suit For ISO Flange

- Pressure Rating For JIS: 5K ~ 20K Suit For JIS Flange

- Material:CI,DI,WCB,CF8,CF8M,ALBC3,A8904A(MOQ)

- Designed in accordance with API 594

- End Connection: Wafer, Lugged (TC6, TC9), Flanged (TC4)

- (Other flange connection please contact Taiwan Valves Centre Co., Ltd.)

- *Technical information is only for reference. Taiwan Valves Centre Co., Ltd. reserves the right to change without previous notice.

Applications

- Flange type dual check valve with full ruber lined is suitable for a country, which have high frequency earthquake. Alternatively, pipe has violently impact and shake often.

- Flange dual plate check valves have two plate in the body, work automatically and most are not controlled by a person or any external control.

- Double Flange check valve is designed to provide a cost-effective solution to your flow control and product shut-off requirements

- Dual plate flange-type valve used in many general applications such as in water distribution, water treatment, dams, power plants and in many other.

- A double flanged valve suited for heavy duty services such as shipbuilding and wastewater plants.

- Flange type check valve can be applied to Chemical, petrochemical industry.

- Dual flange type check valve suitable for Mineral-oil industry

- Double flange check valve used for Heating, air-conditioning, pipelines.

- Full rubber type check valve suitable for seawater, water, cooling water pipeline and…etc.

- The full rubber lined usually used in shipyard, ship plant, seawater desalination, seawater-cooling system.

- The rubber separate medium and the valve of body in order not to contact directly. The full lining type check valve can be used for high concentration brine or acidic medium.

- Full lining type check valve widely applied for water conservancy facilities, sewage treatment plants, and industrial or residential construction industries.

- Dual plate wafer type check valve with full rubber can suitable for pump, sewerage, and reservoir flood control, etc.

- Used in waterproof systems, discharge system, pump, etc.

More Knowledge about TVCCL valve:

TVCCL full rubber type check valve’s material is divided into two choices, NBR and EPDM. Before use, you must pay attention to the temperature of the medium and whether there is a granular object in the medium. Because the rubber can't afford the high temperature and low temperature as well, it is recommended to use it at normal room temperature to avoid the rubber falling off or deforming; and owing to the rubber is unbearably worn, It is not recommended to use the full-rubber type check valve in the cement or the medium which has the presence of particulate matter in pipelines. The installation method is the same as the dual plate check valve. The only difference is that the flange surface of the full rubber type check valve is also covered with rubber, so it is not necessary to add a gasket to fix it.

The Full Rubber type check valve’s inner covering rubber, the medium and the body material are not in direct contact, and the rubber is separate into the medium and the valve body material, thereby achieving the acid resistance and corrosion resistance. The Full rubber type check valve body internal adopts an all-rubber design, which is not easily deposited or produced. And it also reduces the maintenance cost, but the disadvantage is that the rubber is not suitable to keep for a long-time in outside, even if the quality of the rubber is high, the aging phenomenon cannot be avoided.

More Knowledge about dual plate check valve:

Double flanged Type are offered as standard on larger size valves where the lay length of the body permits installation of two nuts between the flanges. Flange type check valve is installed between two flanges using a separate set of bolts for each flange. This setup permits either side of the piping system to be disconnected without disturbing the other side. Flange Type Check Valve with two discs permits installation in a piping system in same manner as any conventional double flanged valve, i.e. studs and nuts per flange; this is one of the easiest connections to be installed or uninstalled from a pipeline. As Double flanged Type Check Valves are fastened to the pipe flanges, assembling or disassembling them is quick and easy. An important point to be mentioned about Double Flange types of end connections is that they are secured with several bolts. Flanged connections are the most common method of connecting valves, regardless of the pressure level (from low to high pressure levels) and valve size (from small to large valves). Flange dual plate check valves work automatically and it is not controlled by a person or any external control. Double flanged Type is offered as standard on larger size valves where the lay length of the body permits installation of two nuts between the flanges. Flange type valves are provided with thru-hole bolting in accordance with API 594, and if you have another standard demand, please send the inquiry to TVCCL.

- Related Products

Dual Plate Flange Type Check Valve

TC4

Because the check valve flange type doesn’t tapping on the flange hole, installation of double...

DetailsDual Plate Wafer Type Check Valve with Full Rubber

TC1

Dual plate wafer type check valve with full rubber is usually used in seawater desalination...

DetailsDual Plate Lug Type Check Valve with Full Rubber

TC7

Lug type dual plate with full rubber lined check valve's body with full rubber lined can effectively...

DetailsDual Plate Full Lug Type Check Valve with Full Rubber

TC10

Full Lug type dual plate check valve is suitable for the environment where the space is small,...

Details- Files Download

- FAQ

Q.What Is Check Valve?

TVCCL Check Valve is a dual plate check valve that conforms to API 594. TVCCL is known as one of the leading manufacturers of Valve in Taiwan since we established.A...

Q. How Do Install Double Disc Check Valve In Pipe?

Taiwan Valve Centre Co.,Ltd. is the professional dual check valve manufacturers in the Taiwan. This information concerning the installation and operation...

Q. What Kind Of Material TVCCL Stock For Dual Check Valve?

Materials Stocked for Dual Plate Check Valve by TVCCLTVCCL, a pioneer in valve manufacturing, has been at the forefront of the industry since 1998. Our expertise...

Dual Plate Flange Type Check Valve with Full Rubber - Flange type with fully lined dual check valve | Made in Taiwan Dual Plate Check Valves Manufacturer | Taiwan Valve Centre Co., Ltd.

Located in Taiwan since 1998, Taiwan Valve Centre Co., Ltd. has been a dual plate check valve manufacturer with all the valves sold to 1,500 clients in 80 countries worldwide. Their main valve products, including Dual Plate Flange Type Check Valve with Full Rubber, dual plate check valves, dual plate full lining type, retainerless check valves, bypass check valves, short and long wafer check valves and spring wafer type for industries, such as oil, shipbuilding, seawater desalination, cooling system and nuclear.

TVCCL has a competitive pricing, reliable quality product and excellent after-sales support, well-down packing. We have received good reputation as being a well-known supplier in supplying reliable quality and competitive price check valves from customers. 20 years of experiences in producing dual plate check valve, excellent after-sales support, OEM / ODM, oil industry, shipbuilding, seawater desalination, cooling system, nuclear industry.

TVCCL, TAIWAN VALVE has been offering customers high-quality and durable industrial check valves for any applications since 1998, both with advanced technology and 25 years of experience, TVCCL, TAIWAN VALVE ensures each customer's demands are met.