Q:API Trim Material For Double plate check valves

TVCCL Check Valve are manufactured with strict compliance to the most recognized international standards all over the world, such as API, ANSI, ASME, ASTM, MSS, NACE, and many others.

TVCCL team is equipped with the required infrastructure to arrive at an optimum dual check valve design to meet all our customer requirements.

The removable and replaceable check valve internal parts that come in contact with the flow medium are collectively termed as valve trim. These parts include valve seat(s), disc, glands, spacers, guides, bushings, and internal springs.

The valve body, bonnet, packing, et cetera that also come in contact with the flow medium are not considered valve trim.

Dual plate check valve trim parts may be constructed of assorted materials because of the different properties needed to withstand different forces and conditions.

Flow-medium properties, chemical composition, pressure, temperature, flow rate, velocity and viscosity are some of the important considerations in selecting suitable trim materials. Trim materials may or may not be the same material as the valve body or bonnet.

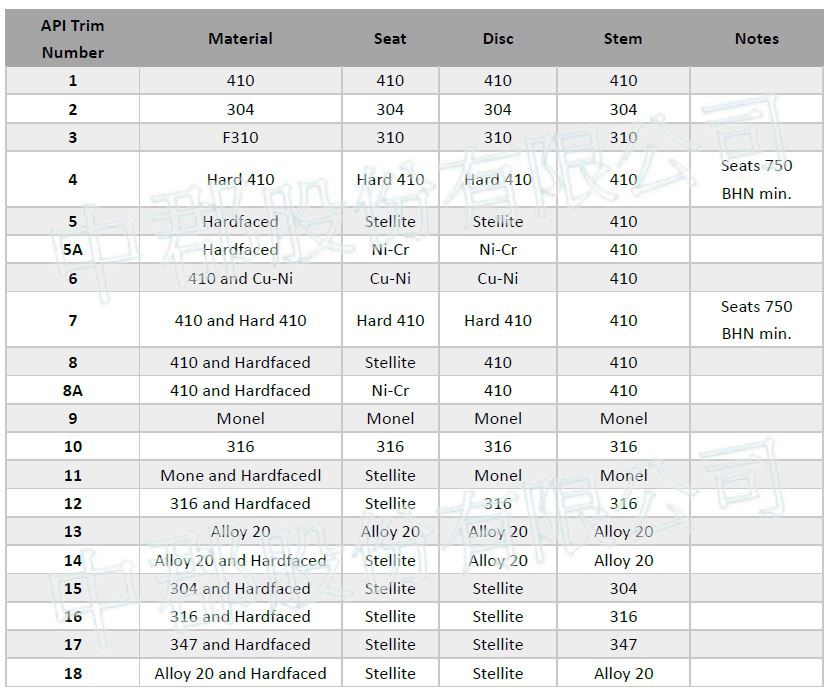

The number corresponding to material used in API 600 and API 602 are termed as trim numbers.

- Related Products

Dual Plate Wafer Type Check Valve

TC0

Fast Delivery: Most orders are shipped within 3-7 days, depending on stock availability. Versatile...

DetailsDual Plate Wafer Type Check Valve with Full Rubber

TC1

Dual plate wafer type check valve with full rubber is usually used in seawater desalination...

DetailsDual Plate Wafer Type Check Valve With Retainerless

TC8

The dual disc check valve with its compact wafer design and low cost have made it a popular...

DetailsDual Plate Lug Type Check Valve

TC6

The dual plate lug type check valve only takes 15-20 minute completely dissemble and reassemble...

DetailsDual Plate Flange Type Check Valve

TC4

Because the check valve flange type doesn’t tapping on the flange hole, installation of double...

Details